In today’s rapidly changing manufacturing era, cutting technology is the cornerstone of industrial manufacturing. With solutions provided in abundance, آلة القطع بالليزرs, plate cutting machines, and ultralarge-format laser cutting machines each have individual but complementary roles. General-purpose laser cutting machines are best suited to cutting medium-sized components, and plate cutting machines are best used to cut thick metal plates. Ultralarge-format laser cutting machines transform productivity to enable free-cutting of gigantic workpieces with micron-level precision.

This in-depth report discusses the technology innovation, manufacturing benefits, and manufacturing applications of ultra-large format laser cutting machines. It also compares them in depth with traditional laser cutting machines and plate cutting machines. Through these comparisons, manufacturers are in a good position to make informed decisions about the technology best suited to their manufacturing needs.

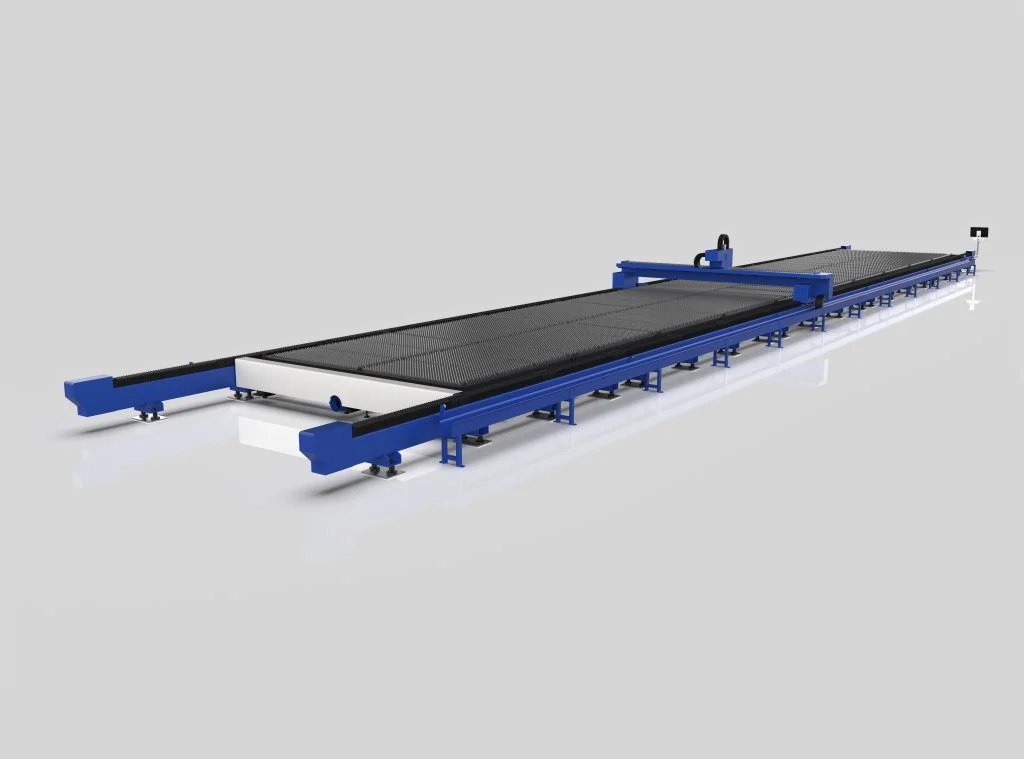

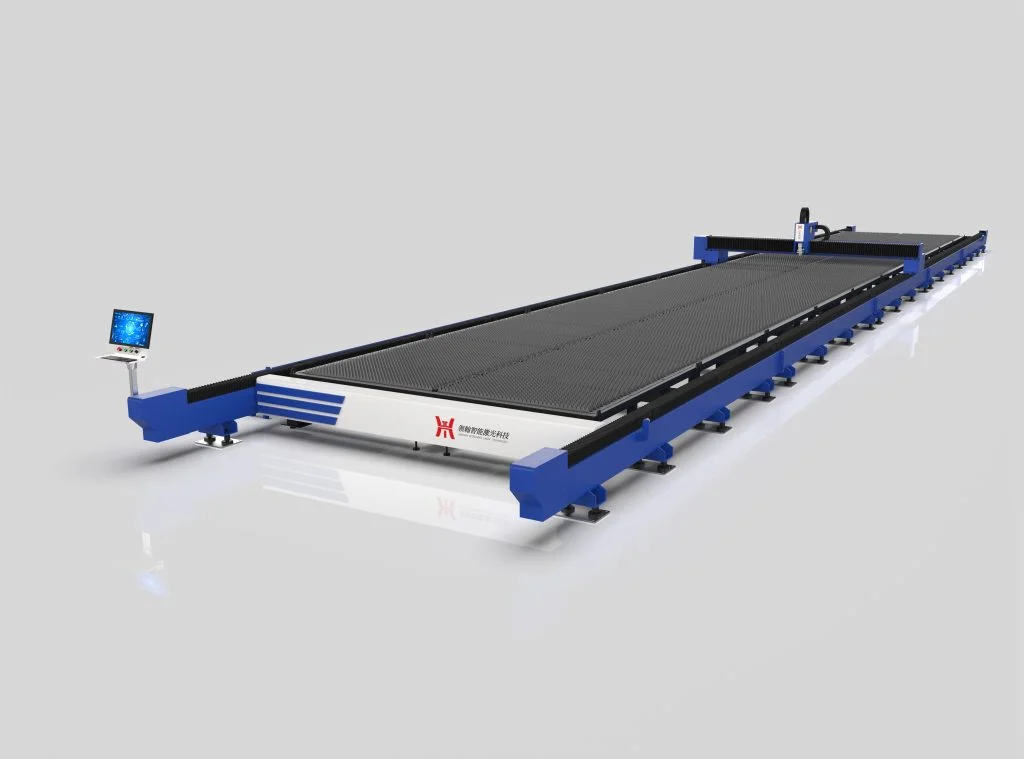

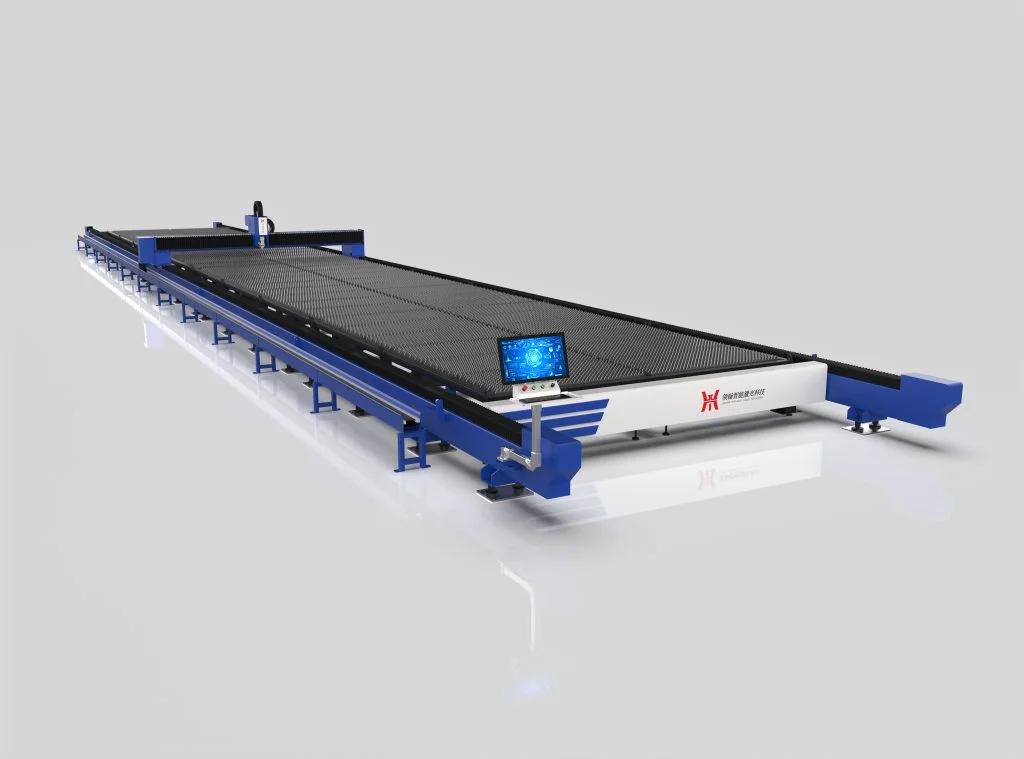

Exploring Ultra-Large Format Laser Cutting Machine

Definition and Primary Functionality

آلة القطع بالليزر ذات الحجم الكبير جدًا is the zenith of cutting machines, used solely to cut gigantic material beyond the range of typical equipment. They will typically have cutting beds between 6 meters and 15 meters in length (with certain custom-ordered material going higher), so full sheets may be worked continuously without second cuts or rework.

Other laser cutting units prioritize high precision cutting within a small working area or high tensile strength for thick plates. Ultra-large-format laser cutting units possess both capabilities and can provide world-class accuracy within a tremendous working area.

Technical Specifications and Features

Ultra-large format laser cutting units now possess stunning technical specifications:

- Laser Power Choices: 10kW to 30kW+ (fiber laser models)

- Maximum Material Thickness: 50mm in carbon steel (with the aid of nitrogen assist gas)

- Positioning Accuracy: ±0.05mm/m (and also used in linear encoder feedback systems)

- Cutting Speed: To 120m/min (is more dependent on material and thickness)

- Automation Suitability: FMS (Flexible Manufacturing Systems) and robotic loading/unloading are suitable

These characteristics make ultra-large format laser cutting machines particularly beneficial to companies requiring large volume production as well as close precision.

Major Advantages of Ultra-Large Format Laser Cutting Technology

1. Unmatched Productivity on Large Components

The most significant advantage of ultra-large format laser cutting machines is that they can cut entire sheets in a single operation. This prevents:

- Material repositioning that requires hours

- Potential alignment errors between cuts

- Future processing requirements

For example, in shipbuilding operations, an ultra-large format laser cutting machine will be able to cut full hull plates (12m x 3m) in one pass, thereby saving up to 60% of production time compared to conventional methods.

2. Improved Cut Quality on Any Scale

Current motion control systems offer standard cut quality for any workpiece size:

- Dynamic Focus Control: Reduces the focal position to the set value over the entire cutting area

- Beam Path Compensation: corrects thermal expansion on long-distance cutting

- Real-Time Monitoring: Vision systems detect and correct possible defects in real time

3. Versatility of Material and Minimum Waste

These machines are capable of processing a wide variety of materials:

- Metals: stainless steel, carbon steel, aluminum, copper, brass

- Composites: fiber-reinforced polymers, sandwich panels

- Specialty Alloys: titanium, Inconel (with appropriate gas mixtures)

Laser cutting accuracy avoids material wastage, particularly important when cutting expensive alloys or oversized material, where even small percentage savings translate into enormous cost savings.

4. State-of-the-Art Automation Integration

Ultra-large format laser cutting machines with advanced automation integrate seamlessly with:

- Automatic Material Handling: Robot loaders and unloaders

- Nesting Software: Optimizes material utilization

- IoT Connectivity: Enables predictive maintenance and production monitoring

Industrial Applications: Ultra-Large Format Supremacy

1. Heavy Machinery Manufacturing

Ultra-large format laser cutting machines engage with:

- Chassis components

- Bucket and blade frame

- Structural frame

2. Defense and Aerospace

Life-critical applications are:

- Aircraft skin panels

- Missile launch systems

- Satellite components

The capability to maintain the tight tolerances (±0.1mm) on large sheet sizes makes the machines indispensable in aerospace manufacturing.

3. Energy Industry Solutions

From wind turbine components to nuclear reactor parts, ultra-large format laser cutting systems machine:

- Tower segments (up to 8m in diameter)

- Pressure vessel parts

- Scaffolding for solar panel mounting

4. Transport Sector

Rail and vehicle industries employ the following systems:

- Body panels of locomotives

- High-speed train components

- Cases of batteries of electric vehicles

Comparative Analysis: Choosing the Right Cutting Solution

Laser Cutting Machine vs. Ultra-Large Format Laser Cutting Machine

| Parameter | Standard Laser Cutter | Ultra-Large Format Laser Cutter |

| Work Area | Typically 1.5m x 3m | 3m x 12m+ |

| Power Range | 1-15kW | 10-30kW+ |

| Thickness Capacity | ≤25mm | ≤50mm |

| Applications | General fabrication | Heavy industry, shipbuilding |

| Automation | Optional | Standard |

Plate Cutting Machine vs. Ultra-Large Format Laser Cutter

| Parameter | Plate Cutter | Ultra-Large Format Laser |

| Technology | Plasma/Oxy-fuel | Fiber/CO₂ Laser |

| Precision | ±1mm | ±0.1mm |

| Edge Quality | Requires secondary finishing | Near-net shape |

| Operating Cost | Lower initial cost | Higher efficiency |

| Heat Affected Zone | Significant | Minimal |

Key Insight: While plate cutting machines remain inexpensive for extremely thick materials (100 mm+), ultra-large format laser cutting machines provide greater precision and productivity for the majority of industrial uses up to 50mm thickness.

Future Trends for Large-Format Laser Cutting

The next-generation ultra-large format laser cutting machinery will be showcased with:

- AI-Optimized Process Control: Real-time machine learning-based parameter optimization

- Hybrid Metal AM: Deposition and laser cutting combined for repair operations

- Environmental Friendly Laser Technology: Reduced energy use and enhanced reflectivity management

- Advanced Safety Features: Next-generation fume extraction and fire prevention technology

Conclusion: Industrial Manufacturing Revolutionized

The ultra-large format laser cutting machine represents a breakthrough technology in industrial manufacturing that has unparalleled capability for large-scale precision machining. While the conventional laser cutting machines and آلة قطع الصفائحs still play certain functions, the unique combination of scale, speed, and precision provided by ultra-large format laser cutting machines makes them the essential tool of advanced heavy industry.

For capital investments in manufacturing equipment on the part of manufacturers, ultimately, the decision depends on:

- Production Volume: Ultra-large format systems are best suited for high volume output

- Material Requirements: Thickness and alloy planning

- Precision Needs: Laser solutions are favored by applications with close tolerances

- Future Growth: Scalability and automation readiness

As industry requirements keep changing, ultra-large format laser cutting machines are going to be a larger contributor to the manufacturing future, bringing the size required for mega-projects and precision demanded by advanced engineering applications.