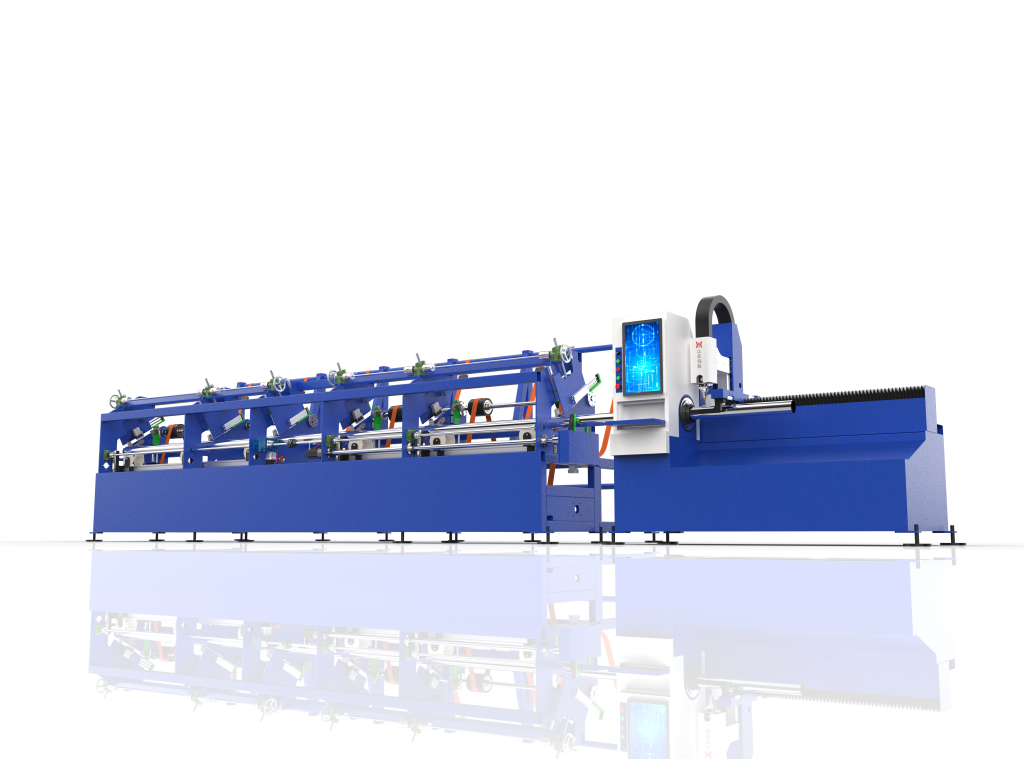

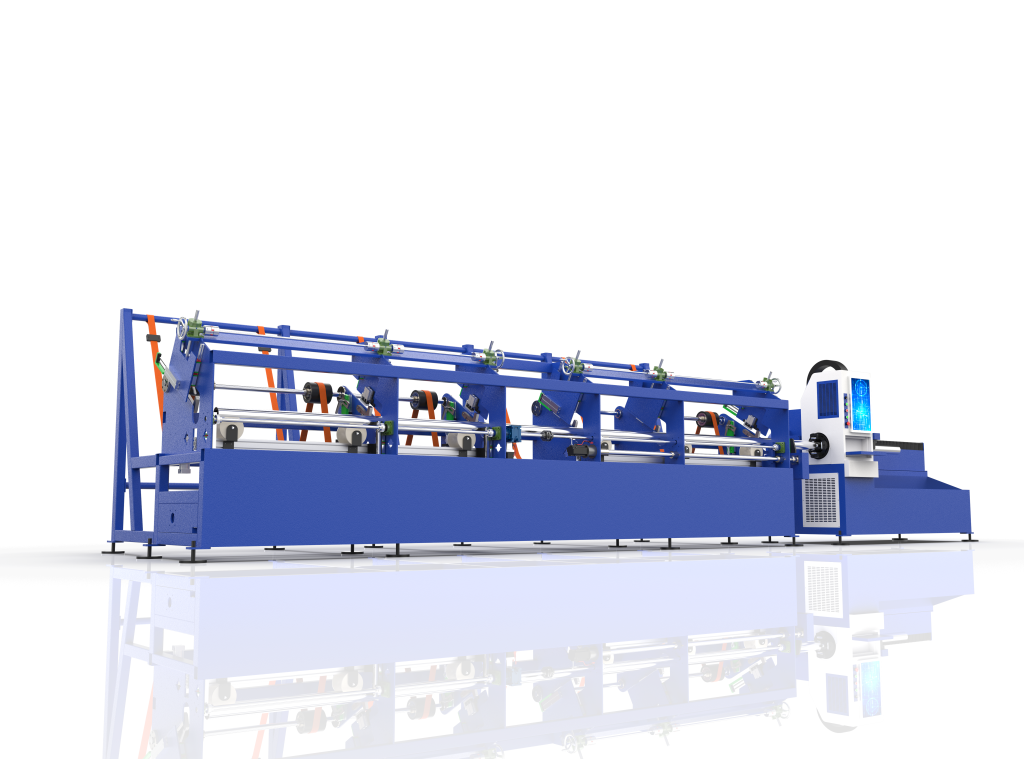

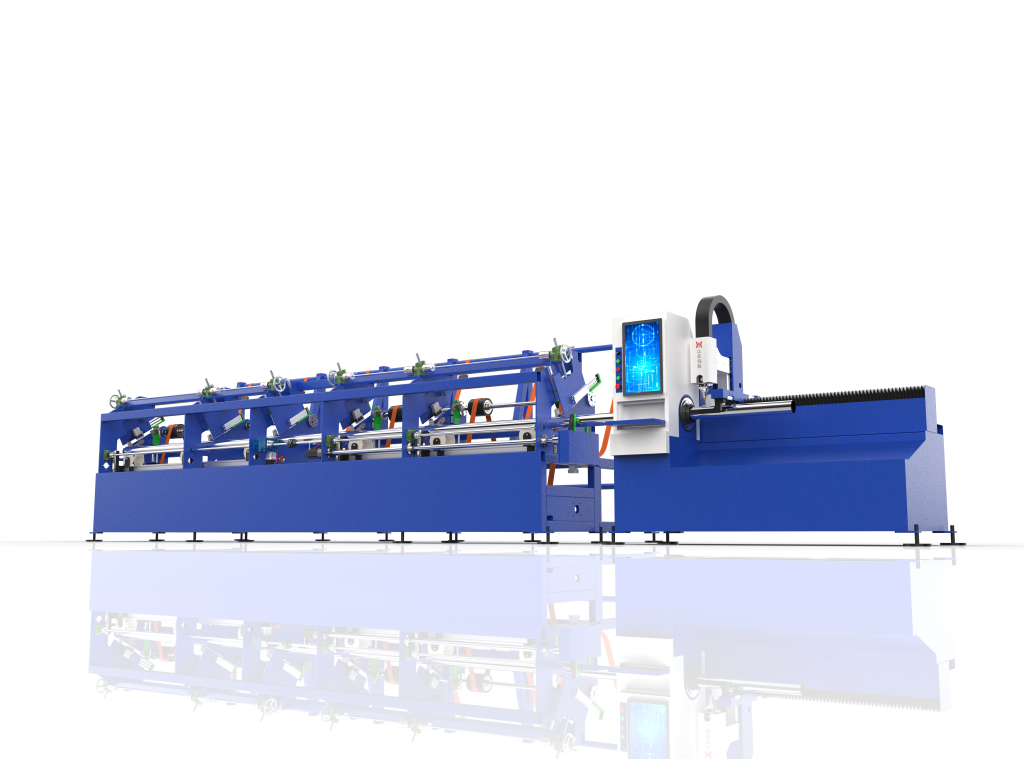

제품 세부 정보

풀링 레이저 튜브 절단기

The Leadhan laser tube cutting machine is a high-performance laser cutting device designed for manufacturers and suppliers, combining precision, speed, and smart technology. This machine not only meets the demands for high-quality cutting but also simplifies operation through various automation functions, reducing the need for manual input. Whether for mass production or customized designs, the Leadhan laser tube cutting machine offers excellent performance and reliable quality

모든 종류의 그루브, 일회성 성형

Product Advantages:

Cost Reduction: By decreasing processing time and material waste, Leadhan’s laser tube cutting machine helps manufacturers and suppliers effectively control costs while improving product quality.

High Precision Processing: Utilizing advanced laser cutting technology, Leadhan’s laser tube cutting machine delivers precise cutting results, minimizing errors and ensuring consistency and aesthetics of the workpieces.

Enhanced Production Efficiency: The automatic feeding function automates the operation process, reducing the need for manual intervention, accelerating production, and significantly improving processing efficiency—ideal for high-volume production needs.

Multi-Material Compatibility: The machine handles various material types and tube thicknesses with ease, including carbon steel, stainless steel, and aluminum alloy, meeting diverse processing requirements across different materials.

기술 사양

풀링 레이저 튜브 절단기

| 扫描切割 | 无 |

| 加工幅面 | 12500mm*3200mm |

| 최대 연결 속도 | 80m/분 |

| 최대 속도 | 0.8G |

| Z 애플리케이션 | 135mm |

| 定位精度 | ±0.05mm/m |

| 重复定位精度 | ±0.03mm |

| 台面承重 | 18000KG |

| 外形尺寸 | 17500*5500*2200 |

| 切割功率 | 6000W 12000W 24000W 30000W |

사진 갤러리

레이저 스캔 컷, 완전 전복

일반 절단

절단 영역에서 에너지 흡수율이 낮습니다.

스캔 컷

절단 영역에서 에너지 흡수율이 높습니다.

Product Features:

High-Power Laser Source: Equipped with a powerful laser source, it achieves high cutting speed and efficiency, suitable for complex workpieces and thick-walled tubes requiring advanced processing.

Pulling Cutting Design: The innovative pulling method ensures stability when processing long tubes, preventing vibration-induced errors and enhancing product precision.

Intelligent Control System: With an advanced control system and user-friendly interface, this machine supports quick parameter setting and easy operation, allowing flexible adjustments to maintain precision during the processing.

Auto-Focusing and Adjustment: The auto-focusing feature allows the cutting head to adapt to changes in material type and thickness in real-time, maintaining optimal cutting conditions for improved efficiency and results.

두 배로 빨라진 속도

동일한 두께 판의 최대 절단 속도가 증가합니다.

200%

높은 반응에 대한 두려움 없음

백라이트의 영향 없이 고반사 방지 소재의 일괄 처리가 가능합니다.

비용 절반으로 절감

가스와 전기의 합산 비용이 가장 높습니다.

38%

접착력과의 작별

다이나믹 페이큘라의 움직임 진폭을 조정하면 공작물 접착력이 크게 감소합니다.