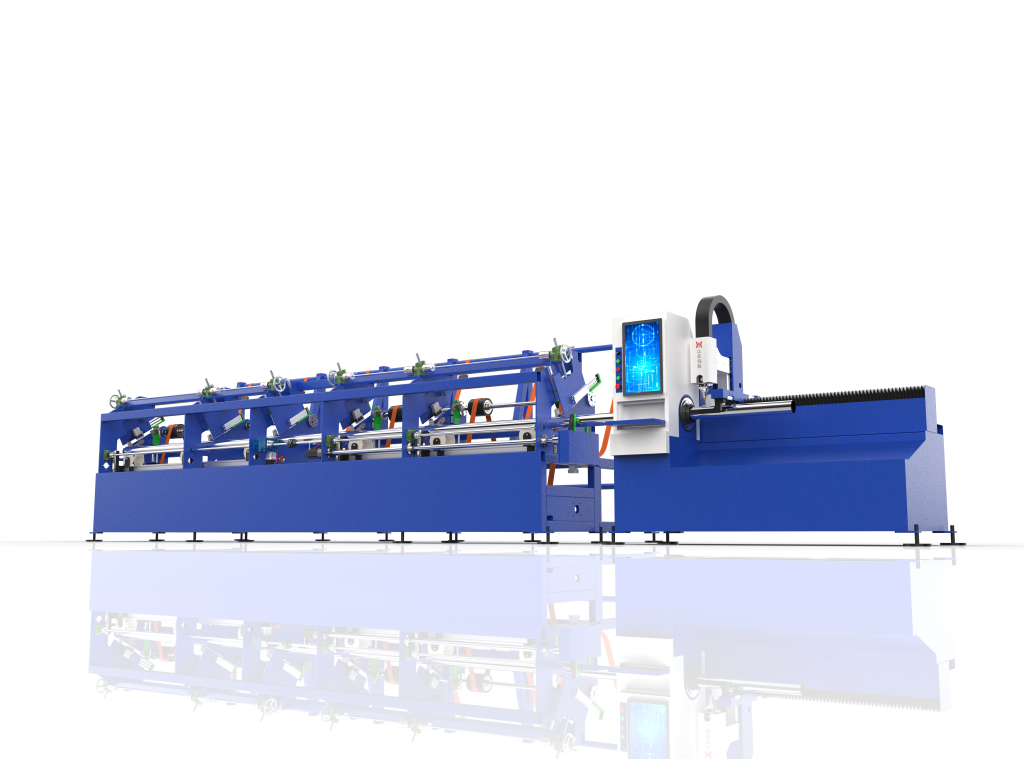

Product details

Pulling laser tube cutting machine

The Leadhan laser tube cutting machine is a high-performance laser cutting device designed for manufacturers and suppliers, combining precision, speed, and smart technology. This machine not only meets the demands for high-quality cutting but also simplifies operation through various automation functions, reducing the need for manual input. Whether for mass production or customized designs, the Leadhan laser tube cutting machine offers excellent performance and reliable quality

All kinds of groove, one-time molding

Product Advantages:

Cost Reduction: By decreasing processing time and material waste, Leadhan’s laser tube cutting machine helps manufacturers and suppliers effectively control costs while improving product quality.

High Precision Processing: Utilizing advanced laser cutting technology, Leadhan’s laser tube cutting machine delivers precise cutting results, minimizing errors and ensuring consistency and aesthetics of the workpieces.

Enhanced Production Efficiency: The automatic feeding function automates the operation process, reducing the need for manual intervention, accelerating production, and significantly improving processing efficiency—ideal for high-volume production needs.

Multi-Material Compatibility: The machine handles various material types and tube thicknesses with ease, including carbon steel, stainless steel, and aluminum alloy, meeting diverse processing requirements across different materials.

Technical specifications

Pulling laser tube cutting machine

| 扫描切割 | 无 |

| 加工幅面 | 12500mm*3200mm |

| 最大联动速度 | 80m/min |

| 最大加速度 | 0.8G |

| Z轴行程 | 135mm |

| 定位精度 | ±0.05mm/m |

| 重复定位精度 | ±0.03mm |

| 台面承重 | 18000KG |

| 外形尺寸 | 17500*5500*2200 |

| 切割功率 | 6000W 12000W 24000W 30000W |

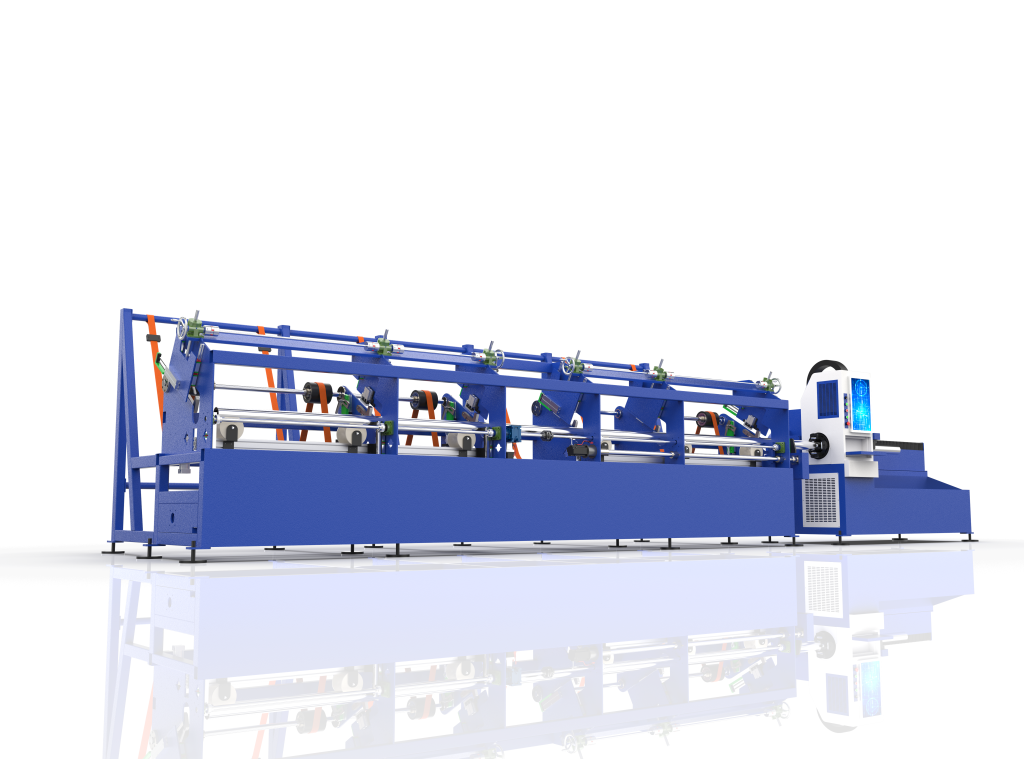

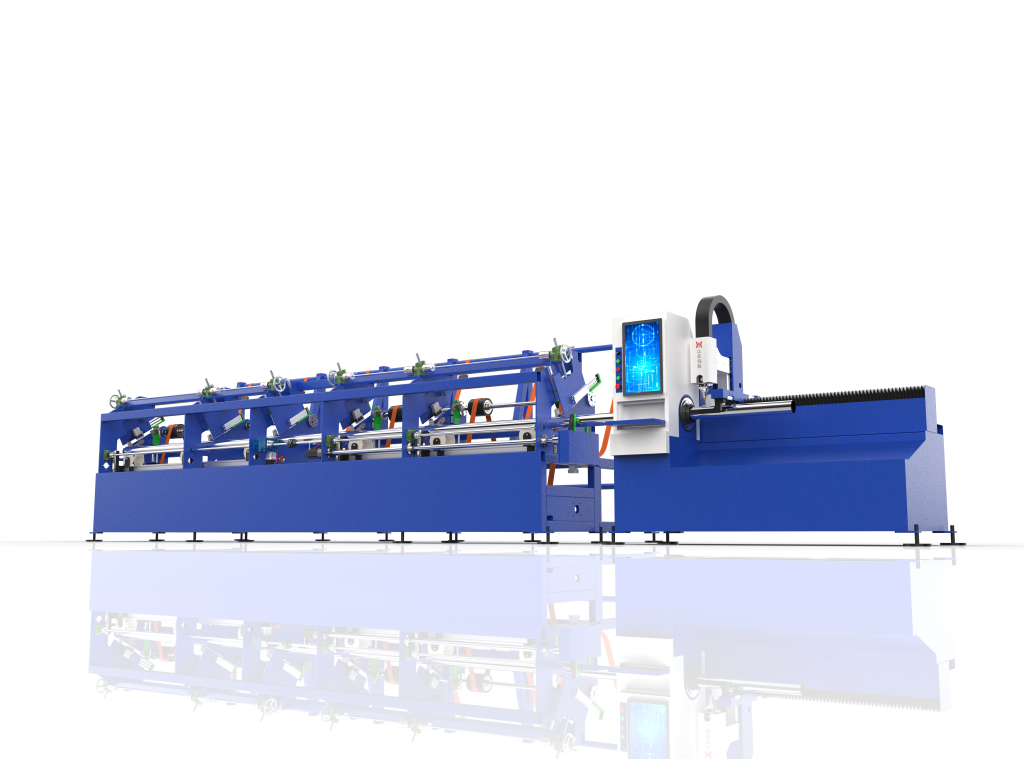

Photo Gallery

Laser scan cut, full subversion

Ordinary cutting

The energy absorption rate is low in the cutting area

Scan cut

In the cutting area, the energy absorption rate is high

Product Features:

High-Power Laser Source: Equipped with a powerful laser source, it achieves high cutting speed and efficiency, suitable for complex workpieces and thick-walled tubes requiring advanced processing.

Pulling Cutting Design: The innovative pulling method ensures stability when processing long tubes, preventing vibration-induced errors and enhancing product precision.

Intelligent Control System: With an advanced control system and user-friendly interface, this machine supports quick parameter setting and easy operation, allowing flexible adjustments to maintain precision during the processing.

Auto-Focusing and Adjustment: The auto-focusing feature allows the cutting head to adapt to changes in material type and thickness in real-time, maintaining optimal cutting conditions for improved efficiency and results.

Double the speed

The maximum cutting speed of the same thickness plate is increased

200%

No fear of high reaction

The batch processing of high anti-reflective material can be realized without any influence of backlight

Cut costs in half

The combined cost of gas and electricity is the highest

38%

Farewell to adhesion

Adjusting the movement amplitude of the dynamic facula greatly reduces the workpiece adhesion