With the dawn of the new era of high-speed production, precision and productivity turned out to be the twin drivers of competition. One of the most revolutionary developments in metalworking was the introduction of pipe cutting machines, and among them, the laser tube cutting machines emerged as a class apart. The reference in this case is the PP6090 pull laser tube cutting machine, where this amount of technology provides producers with unparalleled flexibility, precision, and speed. The report in this case explores the operation of such systems, their advantages of use, and the increasing demand for their use across industries.

The Principles of Pipe Cutting Machines

Conventional pipe cutting machines have been utilized across several industries such as construction, automobile, and aerospace for decades. Conventional systems are usually fitted with mechanical blades, saws, or plasma cutting technology. When in use, they are prone to inherent limitations:

- Mechanical stress-induced material twisting

- Cut quality inconsistency requiring secondary processing

- Increased material loss by the means of wider kerf widths

- Maintenance cost in the form of wear and tear of the blades

Laser technology gave a new turn to pipe cutting operations at their core. Laser tube cutting machines are the pinnacle of this revolution, leveraging laser precision and robotic material handling to deliver improved performance.

How Laser Tube Cutting Machines Operate

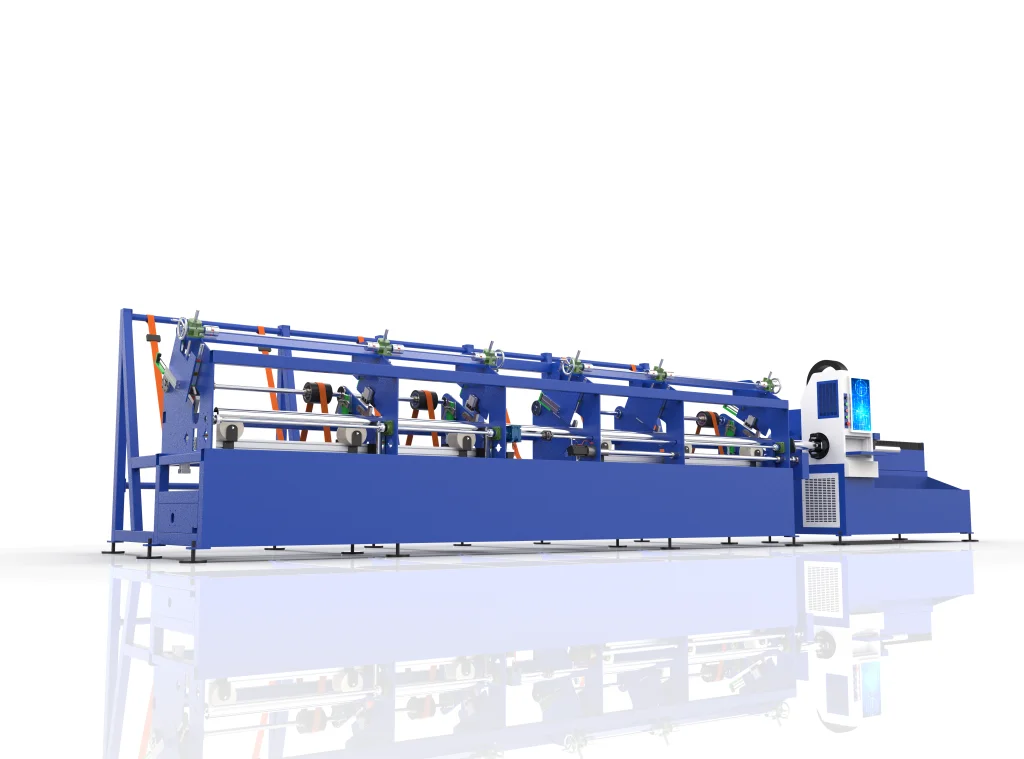

Pulling laser tube cutting machine employs a high-power laser beam to produce precise, clean cuts of the metal tube. The brilliance of the system lies in the pulling that carefully pulls the tube into the cutting zone while the laser head moves along the material length. It is free-cutting technology that minimizes start-stop cycles of the conventional processes.

PP6090 pulling laser tube cutting machine is the best example of such technology with some pioneering features:

1. High-quality Laser Cutting System

- Fiber laser technology with a power range of 500W to 6000W

- Ensures cutting accuracy of up to ±0.05mm

- Cuts tubes of diameter up to 150mm

2. Intelligent Handling

- Auto material feeding system by servo pullers

- Ability to cut tubes of length up to 12 meters

- Integrated clamping system to avoid vibration of the material

3. Intelligent Control Functions

- An offline program CNC machine

- Automatic nozzle switching and refocusing

- Real-time monitoring of cutting parameters

Comparative Advantages Over Traditional Techniques

1. Unmatched Accuracy and Quality

Non-contact laser cutting reduces mechanical stress on the material, thereby avoiding distortion. PP6090 cuts to:

- Surface finish (Ra) of 3.2μm or better

- 60-70% lower heat-affected zones than plasma cutting

- Consistent edge quality with runs to production

2. Increased Production Efficiency

- Continuous cutting process boosts throughput by 40-50%

- Quick changeover from one tube diameter to another

- Cutting and loading operations are done simultaneously

3. Material and Cost Savings

- Thin kerf width (0.1-0.3mm) reduces material waste

- Material is reduced because of the nesting software application

- Less energy is needed compared to CO₂ lasers

4. Design Flexibility

- Capable of creating complex cuts (miters, slots, perforations) in one setup

- Capable of 3D cutting bent tubes

- Capable of integration with CAD/CAM systems

Industry-Specific Applications

1. Automotive Manufacturing

PP6090 pulling laser tube cutting machine is ideally suited to cutting:

- Accurate exhaust system components

- Chassis and roll cage tubes

- Hydraulic system tubes with complex porting

2. Construction and Infrastructure

- Structural steel members with perfect end preparations

- Bespoke pipe fittings for HVAC systems

- Scaffolding components with interlocking members

3. Furniture and Architectural Design

- Ornamental metal furniture frames

- Complex patterned bespoke railing systems

- Lighting fixture components

4. Defense and Aerospace

- Lightweight tubular aircraft frame assemblies

- High-strength hydraulic lines

- Missile and rocket components

Technical Implications for Installation

In integrating a pull laser tube cutting machine into operations, the following are some of the areas that companies can consider:

1. Facility Requirements

- Material and machine floor space requirements

- Power demand requirements

- Ventilation and fume extraction system requirements

2. Operating Requirements

- Operator requirements and training

- Maintenance cost and frequency

- Software compatibility with installed systems

3. Return on Investment Calculation

- Production volume levels required to justify the cost

- The percentage of scrap reduction to calculate

- Labor savings from automation

Future Advances in Tube Cutting Technology

The future tube cutting machines will have:

- AI-driven process optimization for parameter self-management

- Higher IoT connectivity for predictive maintenance

- Hybrid cutting technologies with laser, accompanied by other technologies

- Environmental sustainability aspects for reducing the environmental footprint

Conclusion

The transition from old-fashioned pipe cutting machines to advanced pulling laser tube cutting machines is not merely an equipment improvement—it’s a revolution in the manufacturing mindset. The PP6090 pulling laser tube cutting machine is spearheading the revolution, giving manufacturers a tool to create power to improve quality, production, and competitiveness.

As industry needs move toward more advanced, higher, and more complex precision parts, laser tube cutting technology will become increasingly important. Companies that use these next-generation systems now lay the groundwork to be tomorrow’s leaders in their industry.

Operations looking to invest in this groundbreaking technology will enjoy the PP6090’s optimal balance of affordability and performance, an excellent choice for innovative manufacturers in many different industries.