Product details

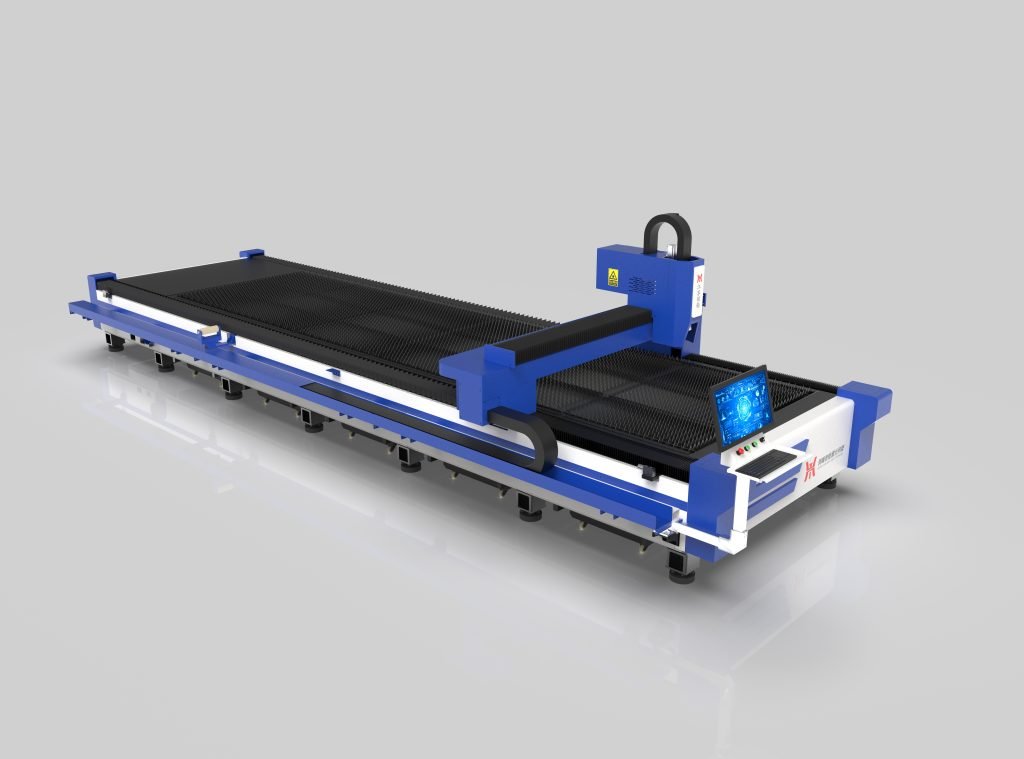

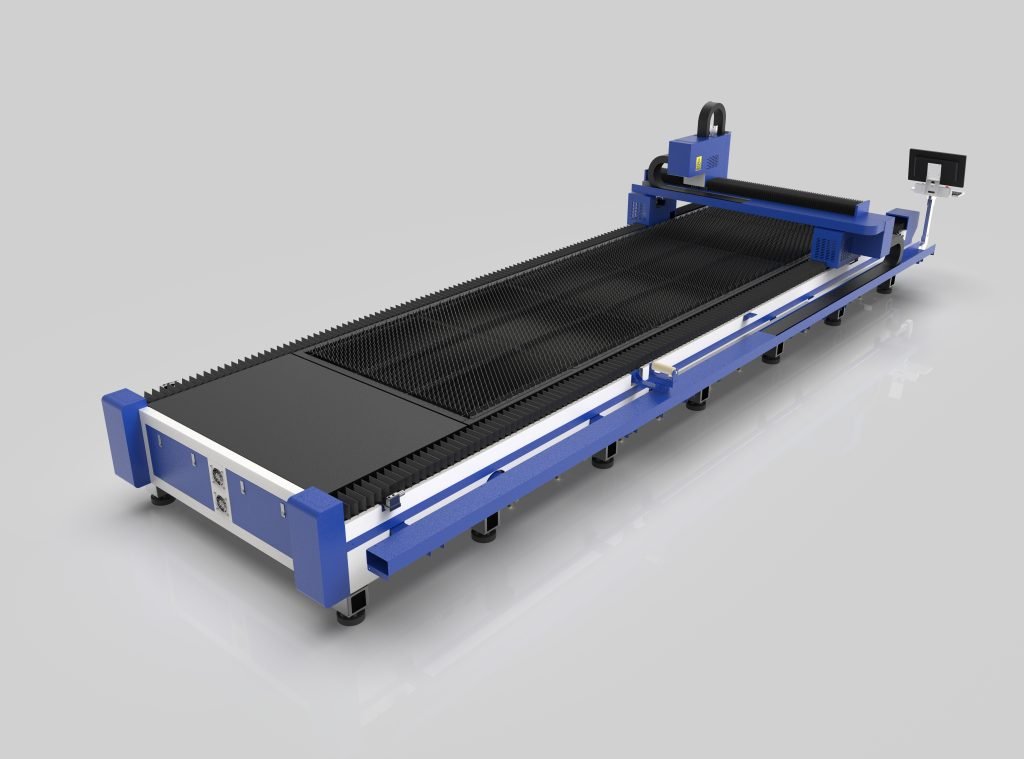

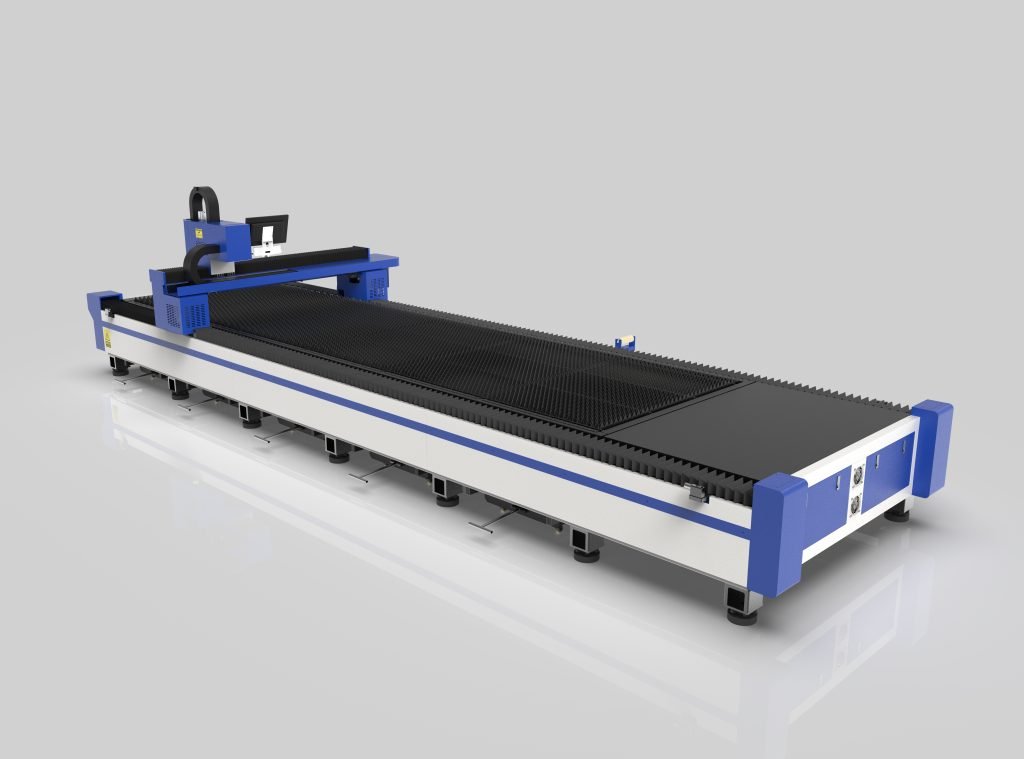

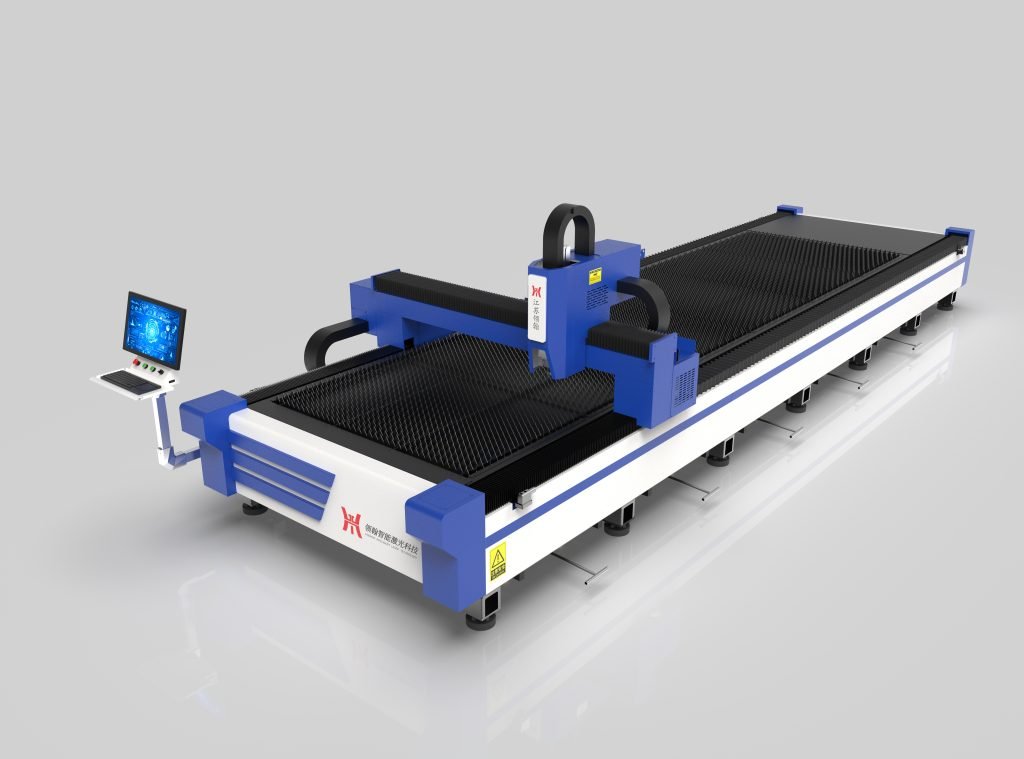

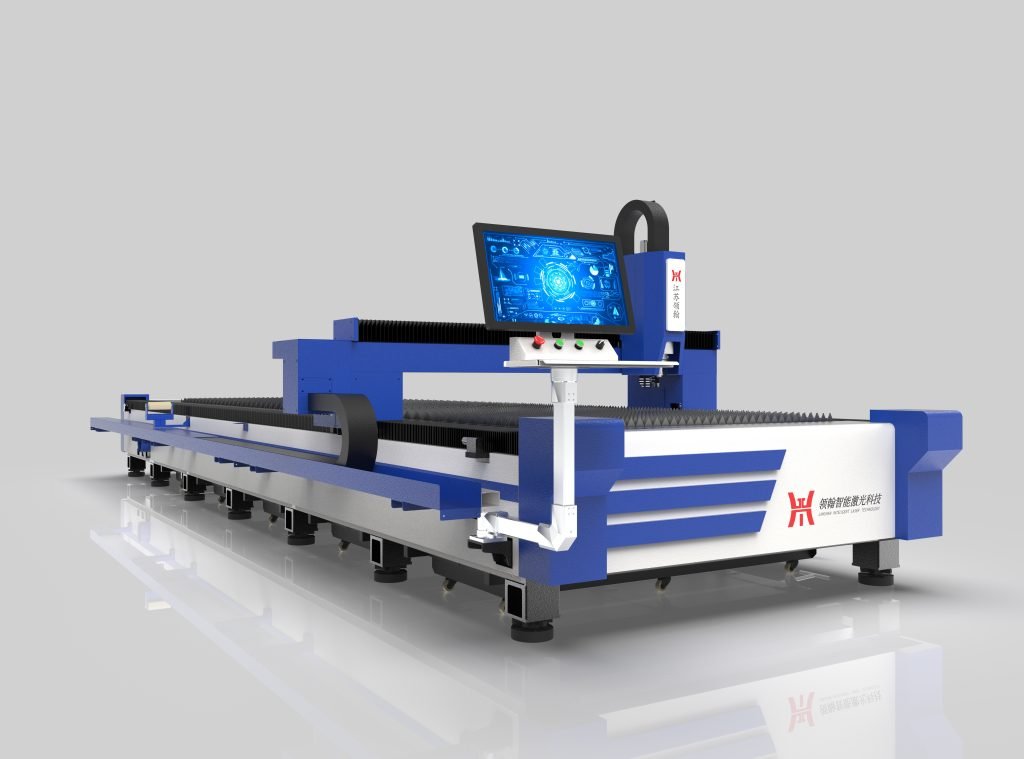

Single table laser cutting machine

The LH single table fiber laser cutting machine is a high-precision, high-efficiency metal processing solution designed for cutting various materials such as high-speed steel, alloy steel, and aluminum sheets. With a cutting area of 3000mm x 1500mm, it boasts a positioning accuracy of 0.03mm and a repeat positioning accuracy of 0.02mm, ensuring precision throughout the cutting process.

Key Features:

Durable Structure & Warranty:

The machine weighs 3500kg and features a robust build for long-term reliability. It comes with a 3-year warranty for both the machine and core components, ensuring dependable performance.

Customizable Laser Power:

Offers a range of laser power from 1500W to 6000W, allowing users to choose the right power level for either high-speed cutting or detailed, fine cutting applications.

Automated Operations:

Equipped with an automatic loading system and a fully automated lubrication system to streamline operations, minimize downtime, and enhance productivity.

Wide File Format Compatibility:

Supports multiple graphic formats, including CAD, DXF, AI, PLT, BMP, DST, DWG, and LAS, making it easy to import and handle diverse design files.

All kinds of groove, one-time molding

With groove cutting module, the cutting of groove can be finished in the blanking stage, which can save the working procedure and reduce the cost

Technical specifications

Single table laser cutting machine

| 扫描切割 | 无 |

| 加工幅面 | 12500mm*3200mm |

| 最大联动速度 | 80m/min |

| 最大加速度 | 0.8G |

| Z轴行程 | 135mm |

| 定位精度 | ±0.05mm/m |

| 重复定位精度 | ±0.03mm |

| 台面承重 | 18000KG |

| 外形尺寸 | 17500*5500*2200 |

| 切割功率 | 6000W 12000W 24000W 30000W |

Photo Gallery

Laser scan cut, full subversion

Ordinary cutting

The energy absorption rate is low in the cutting area

Scan cut

In the cutting area, the energy absorption rate is high

Schematic diagram of laser scanning cutting principle

Double the speed

The maximum cutting speed of the same thickness plate is increased

200%

No fear of high reaction

The batch processing of high anti-reflective material can be realized without any influence of backlight

Cut costs in half

The combined cost of gas and electricity is the highest

38%

Farewell to adhesion

Adjusting the movement amplitude of the dynamic facula greatly reduces the workpiece adhesion